THE LOMEL LABEL

AN INDUSTRY UNICORN THAT ACTUALLY EXISTS

THE MARKET TREND OF DOING MORE WITH LESS

Why should you care about Lomel?

As a tire manufacturer, you’re facing some difficult times. The pressure to reduce labor and materials costs to compete with oversea factories, as well as the demand from the government to improve supply chain traceability can squeeze automotive component suppliers in a tight corner. In a recent interview with Executive Director of the Original Equipment Suppliers Association Charles Chesbrough, he noted that many industry leaders feel they are facing a “continuous downward trend.” Buying conditions have changed– as the commodities market recovers, the price of materials is expected to rise, as well as the energy to manufacture the tires themselves. Indeed, the hike in energy costs will even affect consumers, meaning they will be looking to purchase cheaper vehicles and accessories (like tires). However, while the household budget for vehicles may fall, the product demand is on the rise, especially in emerging markets in Asia. These economic predictions make it likely that manufacturers will be asked to produce more cars and tires, but sell them for less.

All these factors will naturally impinge on production volumes and profit margins. It’s not hard to see why, as Chesbrough says, “there is growing pessimism and uncertainty among the supply base.”

SOLVING A DIFFICULT PROBLEM REQUIRES A UNIQUE SOLUTION

Simply speaking, Lomel can solve all the problems above

Okay, so, how can we combat all these factors without suffering from a lower margin? The answer is simple– increase production output and decrease overhead costs. In other words, do more with less. Right. Simple.

No, really, it is. All you need is an industry unicorn– something completely unique that solves your problems perfectly. You need the Lomel Label from Paragon.

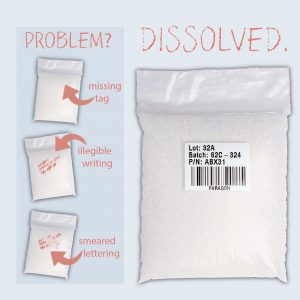

When you’re mixing a batch of meticulously-formulated ingredients, mistakes are just about the last thing you want. Yet, with unlabeled bags and no redundancy protocols, it happens all the time. How many batches have gone to waste because the wrong ingredients were added? How many “mystery bags” of unlabeled ingredients have had to be thrown out?

The patented Lomel® Labeling System was designed to eliminate all these questions and the waste of expensive, ruined product. It produces a human-readable and barcoded Lomel® label that’s printed on the same EVA 160 material used to make Lomel® bags– meaning you can throw the entire thing into the mix with no paper contamination. The Lomel Label is printed on-demand at exactly the moment you need it, so there’s no giant stockpile of unused labels sitting around.

CONFIDENCE IN PRODUCT QUALITY AND COMPLIANCE

Implementing a Near-Zero-Waste System

Once our customers integrate our label into their mixing process, they’ll notice a marked improvement in productivity and a near zero level of product waste. Competitive market conditions favor the efficient, and Lomel surely delivers.

Validation

The Lomel Label is scannable, which allows technicians to automatically identify, record, and validate a bag’s ingredients, weight, and place in the mixing sequence. If an employee is trying to add the wrong bag for the particular recipe, the system indicates an error.

Traceability

Perhaps best of all, the scan records the lot information so you can provide customers or government regulators with detailed production data should a recall occur months or even years later.

HOW AN INDUSTRY LEADER HARNESSED THEIR UNICORN & ELIMINATED HUMAN ERROR

Hexpol Rubber Compounding is one of the world’s largest developers and manufacturers of quality polymer compounds. Their facilities mix and produce countless varieties of thermoplastic elastomers that are used all over the globe. Hexpol works hard to keep pace with their company goals; namely, a close relationship with their customers and a strict focus on innovation and cost efficiency. Their commitment to these values has allowed Hexpol to enjoy sustained growth, even during the recent recession. In order to provide excellent products without increasing their overhead, Hexpol’s production process needs to be free from error.

Hexpol uses Lomel Labels and Lomel Bags to support an efficient rubber mixing process. The combination prevents paper contamination from ruining their batches, and uses a validation code to warn employees if they’re about to add the wrong ingredient to the mix. Both products have reduced batch waste and “mystery bag” waste to almost zero.

“How can I put it in words? When you put a barcode on the bag, it makes everything more accurate. If a guy on the line scans a bag, and it’s wrong, it gives him a red screen and saves the batch from contamination. When the system spits out a label, it asks for a tracking number. If a customer has an issue six months down the line, we can go back and reference that number. We’ve done many things internally to eliminate human error, but the combination of the Lomel bag and the Lomel Label is the best. I think it’s a tremendous product.”

– Spike Weaver, Production Manager for Hexpol

HARNESS YOUR UNICORN

We’re powered by systems integration experts who understand how to implement new technology into your existing business processes. If you’re read to harness your unicorn, we’ll show you how to ride.