- 1. Cost: The cost of color printers, inks and media has never been at a more competitive price point. Highly robust and durable industrial color printers are available starting below $2,000.00, which compares favorably to good quality, monochromatic thermal transfer and direct thermal units. Ink and toner cartridge pricing has improved greatly as color printing adoption has grown, and the capacity of these cartridges has similarly improved. Label stock pricing for color printing is now on a par with that for more traditional direct/thermal transfer use.

- 2. Durability: The technologies of both the color print heads and the media on which they apply the ink/toner have improved to the point where the durability of the labels being created can equal the most environmentally robust combinations in the thermal transfer world. Epson ColorWorks printers, for example, when combined with Kimdura label stock, produce finished labels fully certified to meet the stringent BS5609 standard for overseas shipping.

- 3. Eliminate Label Creation Errors: With true single pass, full color printing now possible, there is far less opportunity for errors between printing software and hardware to occur, and thus create unusable labels.

- 4. Pre-Print Issues: It is no longer necessary to maintain a large inventory of preprinted label stock to introduce color to your printing. Often, only a few sizes of blank label stock are sufficient to print all of your needed labeling, simplifying inventory and tracking.

- 5. Pre-Print Costs: Small batch orders of preprinted labels can be very expensive. The ability to purchase blank label stock and print on-demand color labels can be a far more effective outlay of capital. Print what you need, when it is needed.

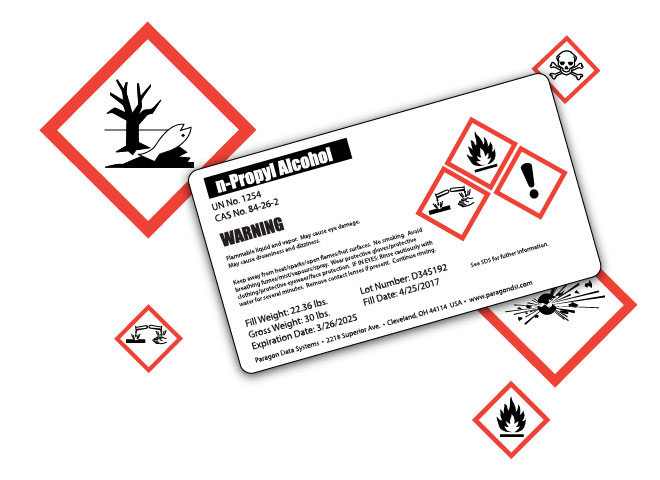

- 6. Alignment Issues: Matching and aligning your printing with preprinted elements is often very challenging, and opens the door for unsatisfactory results. Labels being printed under the GHS guidelines for chemicals, for example, have very strict requirements for finished label output that necessitate very tight label alignment. Unaligned labels will simply be scrap.

- 7. Productivity: Worker time will not be wasted hunting for the appropriate preprinted label or carefully aligning the preprint for proper printing. Single pass full color printing removes the time needed for multiple pass printing, or switching ribbons to add color to the finished label.

- 8. Eco-Friendly: As companies become more concerned with the amount of waste they produce, reducing preprinted labels that must be scrapped when information changes or layout is altered is greatly reduced.

- 9. Color Coding: Using color to highlight key aspects of the product has been shown to greatly reduce errors in the Picking/Packing of products. Important aspect are clearly and quickly discernable, helping to ensure the right product is selected.

- 10. Your Brand: Full color printing can take a needed label from a dry source of information into an attractive extension of your branding. Full color logos and even photo-quality product pictures can be added to make that label an addition sales tool. The human eye is naturally drawn to colorful images. Why not make your label printing another method to make your product stand out?

James Unger is Paragon’s foremost expert on GHS labeling requirements, compliance, and color printing. Subscribe to this series for a weekly update on GHS issues, printing technology spotlights, and further information on color label printing or call 800.211.0768 to speak directly with him about your business’ particular needs.